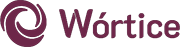

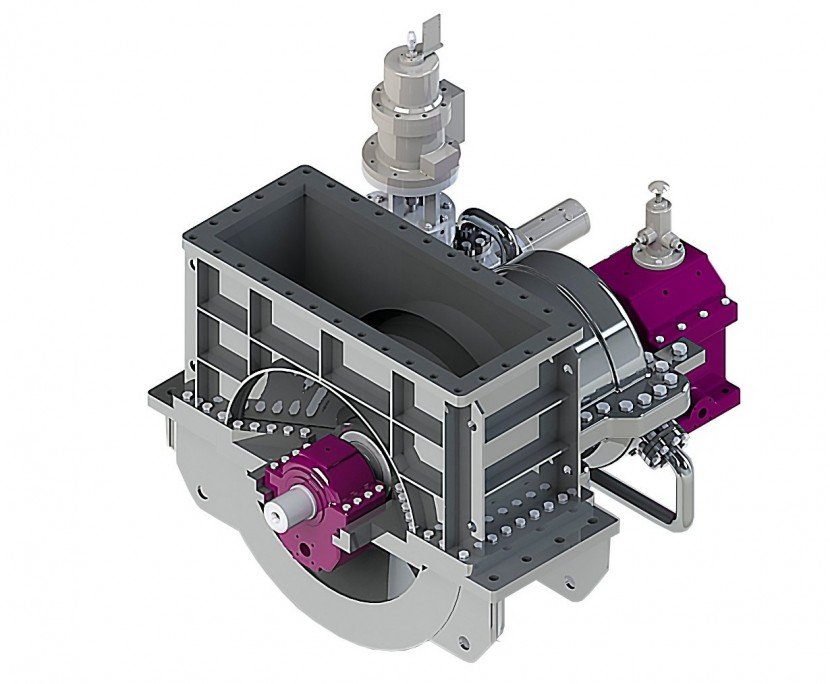

Condensing Steam Turbines

When talking about Condensing Steam Turbines, it is a system that can be applied in several uses within the energy production, whether mechanical or electrical for small, medium and large industries that demand maximum efficiency in their systems.

Thinking of industries that want to generate their own energy, Wortice works with a wide range of condensing steam turbine models.

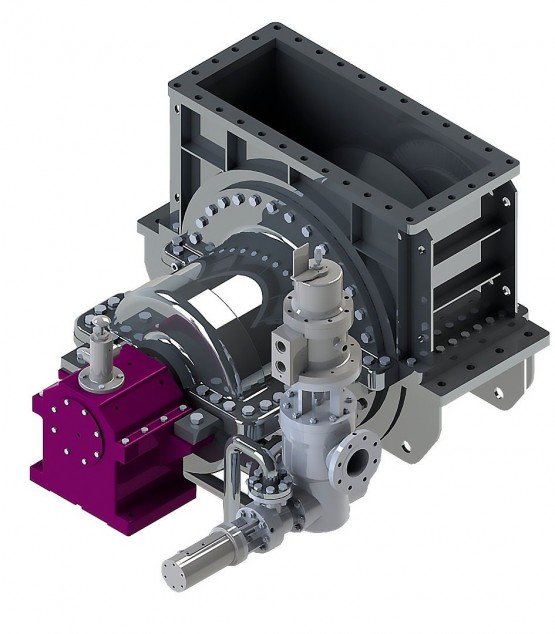

Flowchart

The steam generated in the boiler under high pressure and temperature is injected into the condensing steam turbines, where all its thermal energy will be used by the system. The steam that enters the turbine leaves under vacuum and goes to the condenser, where there is heat exchange with cold water, coming from the cooling tower, where there is condensation of the steam.

After the steam is condensed, it returns to the boiler, closing the cycle. The mechanical work of the condensing steam turbine makes it drive the power generator, which, in turn, generates electricity for the industry.

Request a Quotation

Click on the button, fill out the form and we will get back to you shortly.

Where are Condenser Turbines recommended?

Wortice’s condensing steam turbines can be used in the most varied industries, focusing mainly on their own power generation or those wishing to replace their current turbines.

In addition to industries, Wortice also supplies condensing steam turbines to engineering companies that supply turn-key plants and need this turbine model for their machinery.

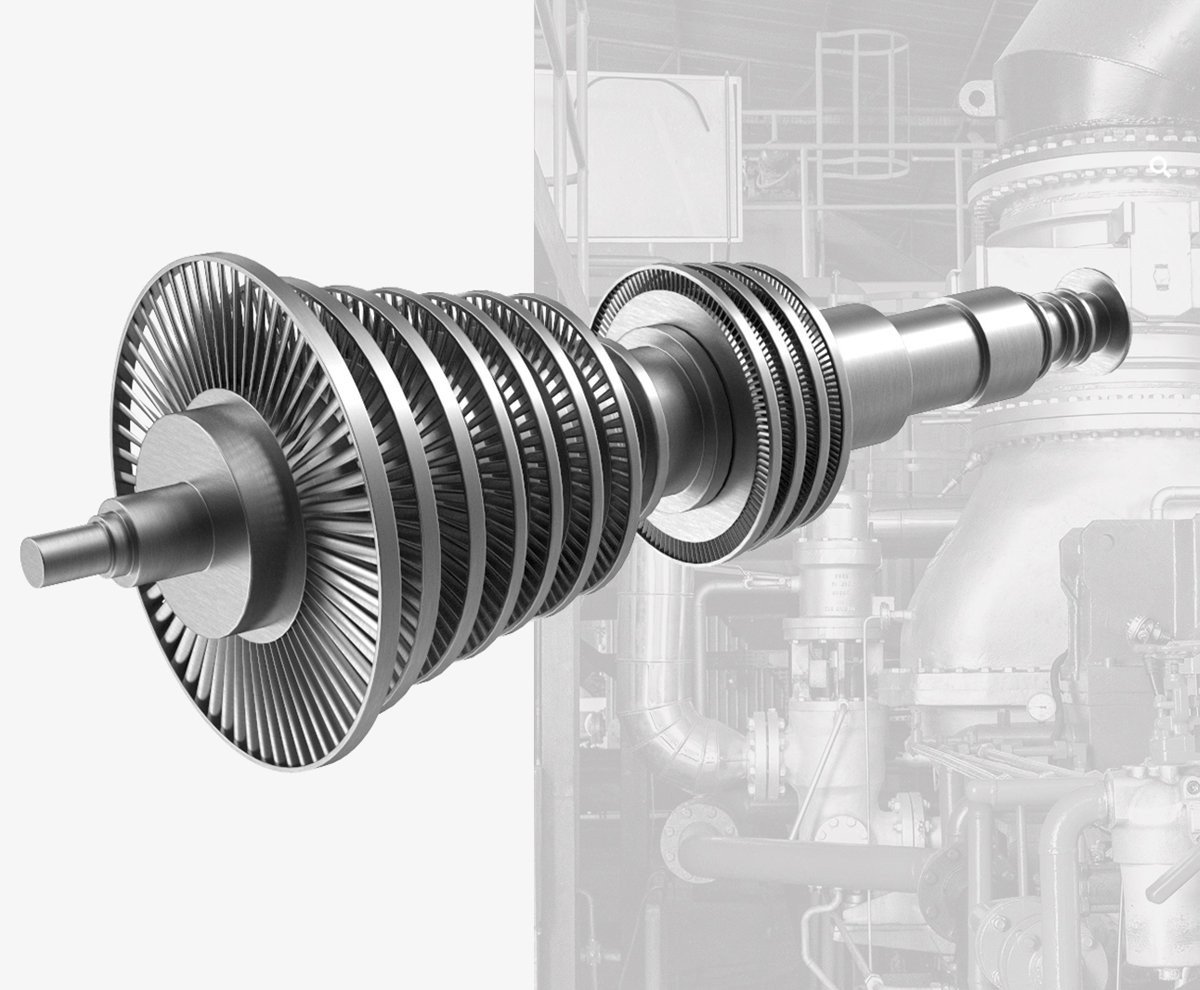

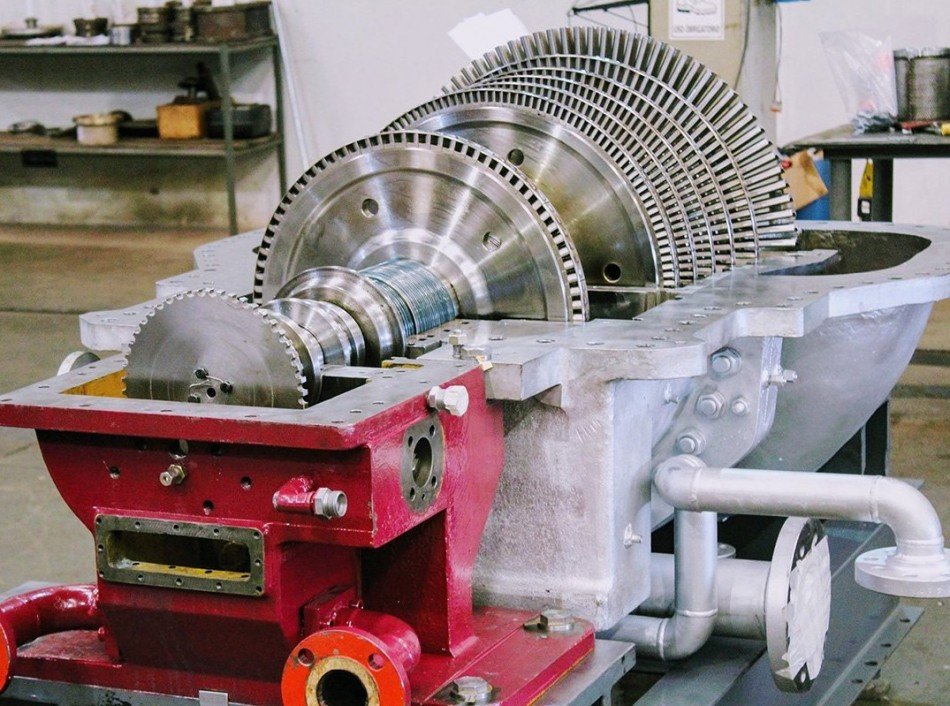

Is there a specific process in the assembly of Condensing Steam Turbines?

Wortice’s condensing steam turbines undergo a rigorous quality process from their conception to their components manufacture, following technical standards that make the product more robust and able to meet the demand of industrial use.

The differential of the assembly

Wortice has a team of professionals with extensive experience in the assembly of condensing steam turbines, with a team of employees with extensive knowledge in the assembly of power generation systems.

How is the system sized?

Our condensing steam turbines are sized based on the specific needs of each situation.

Each quote is unique as it is based on the specific needs of each customer. For this reason, Wórtice analyzes each situation in a serious and pragmatic manner.

One of Wórtice's differentials stands out during the evaluation process, which is a thermal balance to determine if it is really worth your company investing in this process. This evaluation is offered to the customer free of charge and is carried out by our specialists.

How long does it take to manufacture Turbines?

The production time for condensing steam turbines varies according to the project and its needs.

Therefore, when we meet with the client to analyze the project and start the work, we will have a forecast of the time that project will require.

Wortice Turbines Power Range

| Equipment Model | Power (kW) |

| WXC 500 | 500 |

| WXC 1000 | 500-1000 |

| WXC 1500 | 1000-1500 |

| WXC 2000 | 1500-2000 |

| WXC 2500 | 2000-2500 |

| WXC 3000 | 2500-3000 |

| WXC 4000 | 3000-4000 |

| WXC 5000 | 4000-5000 |

| General Specifications |

|

Rotation (RPM) According to Project Maximum steam inlet pressure bar (a) 42 Maximum steam inlet temperature bar °C 450 Maximum steam outlet pressure bar (g) Vacuum |

Factory Warranty Condensing Steam Turbines

One of Wortice’s biggest differentiators is not only providing the maintenance and manufacturing of high quality and performance condensing steam turbines, but also its full warranty. In addition to it, the equipment is field tested before delivery to the customer.

Where can we find Condensing Steam Turbines?

If you are looking for condensing steam turbines for your own power generation or even to increase the efficiency of your industry, Wortice provides the customized and adequate solution for your project, with a team with over 40 years of experience in maintenance and production of power generation systems.