Micro steam turbines for electric power generation of up to 300 kilowatts

Wortice’s innovation

Wortice is a pioneer in Brazil in the microgeneration of electric energy from steam turbines, providing the market with equipment of up to 300 kilowatts for generating electric energy with steam, that is, micro steam thermoelectric plants.

The micro steam turbines developed by Wortice are specific equipment to meet a specific market area, in which the economic viability of projects for the generation of electric energy could not be achieved.

How it worked

It is common in the market the paradigm that a power generation from thermoelectric plants becomes economically viable for power generation greater than 1 Megawatts, so, up to now, there was no equipment designed and developed to operate powers lower than 500 kilowatts, which was commonly applied in projects, were equipment designed for large generations, operating at reduced power.

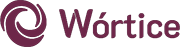

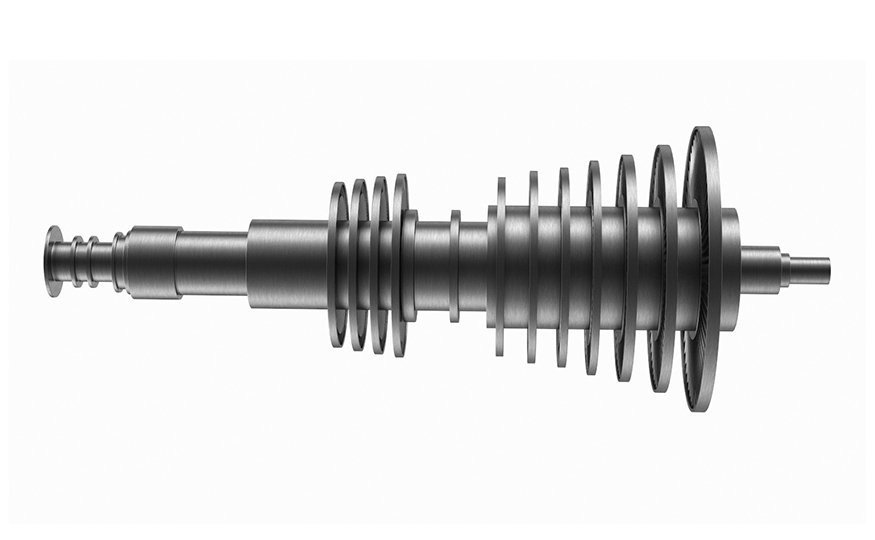

Micro Wortice steam turbines

Wortice sought to understand the market's need, and developed equipment for operation at low powers, so that they presented excellent economic viability in the projects, with micro steam turbines in the market for electricity generation, in two conceptions:

- Micro back pressure steam turbines;

- Micro condensing steam turbines.

Another fundamental point for the development of micro turbines was the operation with reduced pressures, being possible to install a power generation in industries where there is already a boiler installed, working with pressures of 10 and 15 bar, where Wortice provides a solution to adapt the steam from the existing boiler, with the implementation of the micro power generation thermoelectric plant.

Condensing Steam Turbines

Learn more

Back Pressure Steam Turbines

Learn more

Applications

Wortice’s micro steam turbines are extremely viable for use in energy reuse, whether for surplus, use of steam from the production process or for use of industrial waste, which in turn can become a headache for the customer, for are environmental liabilities.

Therefore, any industry that has steam in the process and/or biomass as waste from its production, such as:

- wood chip;

- saw dust;

- biomass;

- rice husk;

- fruit lump;

- fruit pomace.

They are fully viable to generate their own energy.

Result

Energy self-sufficiency can transform the financial result of industries, significantly reducing spending on electricity, which in many cases can be the main cost and/or expense of a production process, palpably bringing the return on investment in a few years for the entrepreneur.

Interested in it? Contact us and speak with one of our experts.