Bearings

Bearings are fundamental pieces of equipment, the main objective of this component is to facilitate the desired movement, minimizing friction and improving machine performance.

Bearings are classified according to the type of operation, the movements allowed or the directions of loads (forces) applied to the parts. Bearing applications cover virtually all industries that employ mobile or rotating components and equipment.

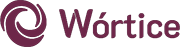

Wortice offers bearing maintenance and repairs, in addition to the manufacture of this component itself, and its main use in the power generation sector is in steam turbines, gearboxes and power generators.

What are Bearings?

Bearings are devices that allow movement in a fixed direction between two parts, usually rotational or linear movement. Bearings can be grouped by the way they work. There are several types of bearings, however, the most common are rolling bearings and plain bearings

Bearings are mechanical components developed to allow the support of a shaft while it rotates, in order to always keep it in its original position.

The factors that influence the choice of bearings are:

- Load capacity

- Lifespan

- Available space

- Working speed

- Precision

- Noise level

- Stiffness

- Axial displacement

- Misalignment

- Easy assembly

- Easy disassembly

Types of Bearings

Rolling Bearing

When the bearing has a rolling, it’s called a rolling bearing, due to the rolling friction.

In rolling bearings, the moving surfaces are separated by balls or rollers, and then, friction rub is replaced by rolling friction.

As the contact area is small and the stresses are high, the rotating parts of the bearings are made of hard, high-strength materials.

The biggest advantage of rolling bearings is that the friction at start-up is almost equal to the operating friction in contrast to the initial metal-to-metal friction of friction bearings.

Bearings can be classified as radial or axial.

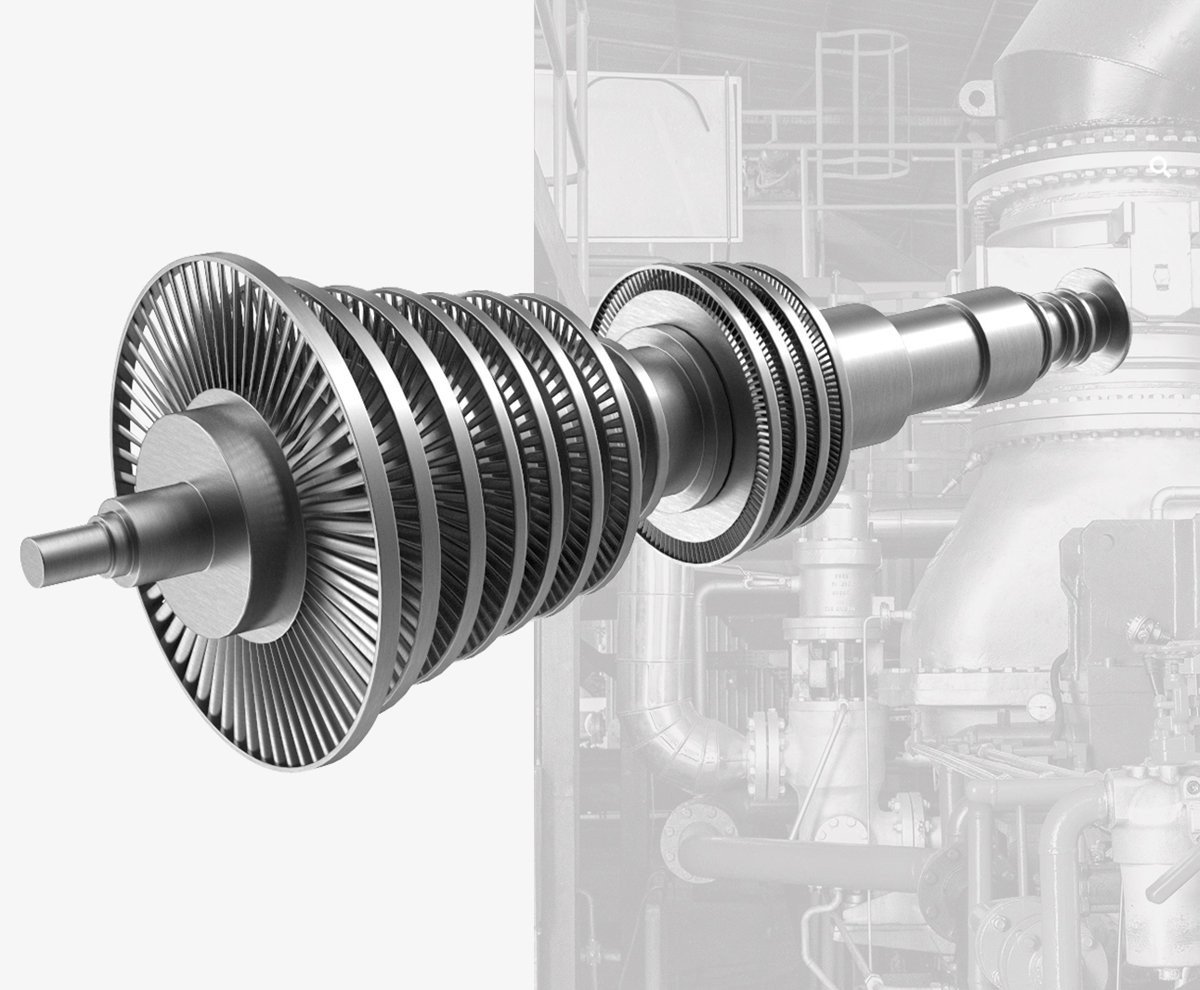

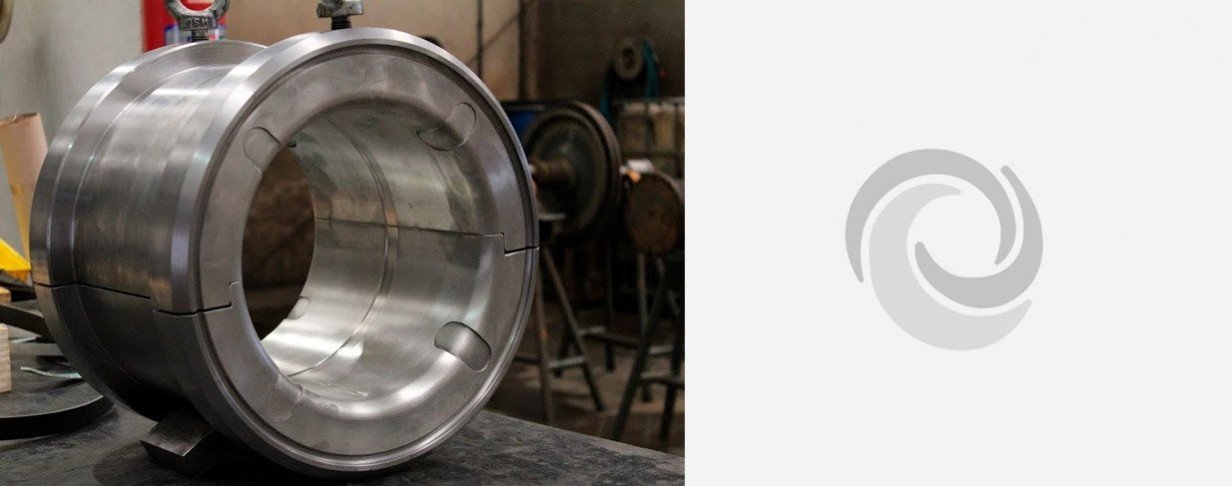

Slip Bearing

When the bearing has a bushing, it’s called a plain bearing, due to the type of friction, which in this case is sliding.

Sleeve bearings have a bushing that has the function of receiving direct friction with the shaft surface. According to the type of effort, we can classify the bearings into:

- Bearings for radial loads

- Thrust bearings

Bushings are generally cylindrical and have a hole to allow the lubricant to pass through. They may also have slots to improve the passage of the lubricant.

Request a Quotation

Click on the button, fill in the form and we will get back to you shortly.

Request a Quotation

Equipment that can be used

In a thermoelectric plant, bearings can be used in the following equipment:

- Steam turbines

- gearboxes

- Power generators

Babbitt bearing (patent metal)

Babbitt metal can be one of several alloys used as a bearing surface in plain bearings It’s a white, soft, non-ferrous alloy that is used to provide a bearing surface.

Bearings are used in engines to support moving mechanical parts and protect them from frictional degradation. Babbitt metal also has properties that help reduce friction, which makes it a good material for use in a plain bearing. Babbitt metal is soft and can be easily damaged if not treated properly.

This would make it look unsuitable for use as a bearing surface, however the alloy structure is made up of small hard crystals, which are dispersed in a softer alloy matrix. This means that as the bearing wears out, the harder crystal is exposed and a path for the lubricant is provided.

The bearings Babbitt 's work by providing a low coefficient of friction, achieved primarily by two means.

First, there is the fact that the bearing itself has a low coefficient of friction, so even without lubrication, a Babbitt bearing will have much less friction than another metal such as steel or cast iron.

However, by adding lubrication, Babbitt bearings can have a significantly low coefficient of friction, even lower than ball bearings.

Wortice

We have a great knowledge in the industrial bearings market, with professionals with over 40 years of experience.

We offer services on all models of equipment and all manufacturers.

Our objective is to offer efficient solutions, with specialized technical maintenance, aiming at excellence in quality, contributing to the industrial sector in an ethical and productive way.

We have specialized technical service at the factory and on site for:

- Corrective bearing maintenance

- Preventive bearing maintenance

- Predictive bearing maintenance

- Bearing Maintenance focused in the reliability

- Reform, retrofit and modernization in bearings

- Operational interventions in bearings

- Replacement of parts and components in bearings

- Equipment installation, commissioning and start-up on bearings

- Inspections with technical report elaboration and performance monitoring in bearings

We also have specialized technical assistance on call for bearings, with a team available for field service and a manufacturing structure with 24-hour availability for services on bearings.

- Total excellence in service dedicated to each customer

- Professionals with over 40 years of experience

- Specialized Technical Team with engineering support

- 24 hours a day, 7 days a week emergency call

- Technical team available for on-site assistance

- Factory and Team available 24 hours a day

- 100% Brazilian technology

- Environmental & Social Responsibility

Learn more about the Bearing Services offered by Wortice

With physical headquarters located in Sertãozinho, a city located in the country of São Paulo state, Wortice is a company that manufactures and provides maintenance on bearings, which in addition to having specialized workforce, operates in accordance with all safety standards, always aiming at total excellence in the service dedicated to each customer.

In addition to offering bearing solutions, Wortice offers different industrial solutions in power generation, such as:

- Steam turbine manufacturing

- Turn Key Thermoelectric Plants

- Specialized engineering

- Maintenance on condensers, steam turbines, gearboxes and power generators

- Manufacture of parts and components

For more information about bearings or other services that Wortice offers, contact us by phone (16) 3511-0220 or send an email to comercial@Wortice.com.br