Off-season Maintenance in Sugar and Ethanol Plants

Request a Quotation

Click on the button, fill in the form and we will get back to you shortly.

Request a Quotation

Perform preventive maintenance on your ethanol and sugar plant, during the off-season, on steam turbines, gearboxes, parts, accessories, components, thermoelectric plants at Wortice.

Brazil is a major global player in agribusiness is already a statement known to all. Thanks also to technology solutions, our rural producers have been able to reach ever higher levels of income, together with the reductions in operating costs resulting from a good execution of preventive maintenance in the off-season in steam turbines, gearboxes, parts, components, accessories and thermoelectric plants.

The entire year is favorable for the cultivation of the most different crops. But for ethanol and sugar mills, there is an essential period for the maintenance, conservation and ensure of operation of the equipment: maintenance in the sugarcane off-season

It’s through preventive maintenance in the sugarcane off-season, which is the ensure of the correct operation of steam turbines, gearboxes, parts, accessories, thermoelectric plants and components throughout the harvest.

Wortice specializes in off-season preventive maintenance in ethanol and sugar plants and predictive off-season maintenance in the sugar-energy sector, performing maintenance on steam turbines, gearboxes, thermoelectric plants, parts, accessories and components.

Wortice has a team of professionals with experience and know-how for over 45 years in the field of steam turbines, gearboxes, parts, accessories, components and general maintenance in thermoelectric plants.

Harvest and off-season periods in ethanol and sugar mills

In Ethanol and Sugar mills, it’s quite common for the harvest to begin in May, and lasts until November. After this period, another so-called off-season begins, which in ethanol and sugar mills usually takes place between December, and can last until April.

The off-season is in the period before the harvest, and it’s at this stage that a series of maintenance is carried out at the ethanol and sugar plants, including preventive maintenance in:

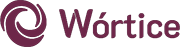

- Steam turbine

- Gearbox

- Thermoelectric plants

- Parts

- Accessories

- Components

In this content you will learn more about this topic.

Request a Quotation

Click on the button, fill in the form and we will get back to you shortly.

Request a Quotation

What is Preventive Off-season Maintenance?

The off-season is the period of the year established between one harvest and another, when, for example, arable areas are used for other crops with a shorter production time. This time, the soil can benefit and have its characteristics renewed.

But it's not just for the land that the off-season is important. It’s also essential for machinery and equipment that cannot be interrupted during the harvest, which could lead to production losses and high costs.

Therefore, it’s highly recommended to carry out preventive maintenance in the off-season, in steam turbines, gearboxes, thermoelectric plants, parts, components and accessories in ethanol and sugar plants.

Preventive maintenance in the off-season, as the name implies, prevents future problems, failures, interruptions and possible unnecessary stops of steam turbines, gearboxes and thermoelectric plants. Maintenance in ethanol and sugar plants is usually carried out according to the manufacturers' recommendations to always maintain:

- Process quality;

- Full operationalization;

- Avoid overloading equipment.

The Engineering department of Wortice , a company located in Sertãozinho, in the country of São Paulo state, specialized in the maintenance of steam turbines, gearboxes, thermoelectric plants, parts, accessories and components during the off-season, is formed by experienced professionals. And experts working with the most advanced features, modern concepts and security standard to:

- Optimize processes;

- Reduce costs;

- Improve the operation of machinery;

- Prevent rework.

What is Predictive Off-season Maintenance?

In ethanol and sugar plants, preventive maintenance in the off-season is defined as the action used to prevent the appearance of problems in steam turbines, gearboxes, thermoelectric plants, parts, components and accessories, which could affect production and generate costs. Unnecessary.

Request a Quotation

Click on the button, fill in the form and we will get back to you shortly.

Request a Quotation

Predictive Maintenance in ethanol and sugar plants

Predictive maintenance in the off-season can be understood as:

- Monitoring the activities of steam turbines, gearboxes, thermoelectric plants, parts, accessories, components, through frequently collected data, through technical visits, in order to define the operational situation of each of them, and what may occur negatively with each equipment.

In order to carry out preventive maintenance in the off-season in ethanol and sugar plants, some parameters are used, such as:

- Fluid analysis;

- Vibration analysis;

- Thermography;

- Process parameters.

The combination of these parameters can indicate scenarios of possible problems, still in the initial stages, which can lead to production losses and high costs in ethanol and sugar plants. Thus, early detection, the correction becomes easier, faster and cheaper.

Predictive maintenance goals during the off-season

- Anticipate the need for maintenance services;

- Eliminate the chance of unnecessary disassembly or repairs;

- Increase equipment availability time;

- Reduce forced stops;

- Increase the lifespan of equipment;

- Increase the reliability of equipment performance;

- Pre-determine manufacturing interruption failures.

Wortice team is also specialized in predictive off-season maintenance on steam turbines, gearboxes, thermoelectric plants, parts, accessories and components in ethanol and sugar plants. In order to do it, it employs the most modern techniques, combined with the knowledge of its professionals to ensure accuracy, credibility and excellence.

Maintenance in Wortice off-season is safety!

As we have seen, performing off-season maintenance on steam turbines, gearboxes, thermoelectric plants, parts, accessories and components in ethanol and sugar plants is essential to reduce the losses that can occur over time and also to reduce costs with procedures for emergency maintenance and corrective maintenance in ethanol and sugar plants. With the increasingly competitive market, the time lost in a production process can be a very big problem for any industry.

Therefore, in ethanol and sugar plants, monitoring steam turbines, gearboxes, thermoelectric plants, parts, components and accessories, is the initial step for all strategic maintenance planning, during the off-season in ethanol plants and sugar. It’s possible to create a schedule for the replacement of parts, components and accessories in steam turbines, gearboxes and thermoelectric plants, knowing that failures may occur due to the excessive use of equipment and machinery in ethanol and sugar plants.On the other hand, the monitoring carried out by periodic inspections allows mapping possible future failures.

Request a Quotation

Click on the button, fill in the form and we will get back to you shortly.

Request a Quotation

Predictive and preventive maintenance in ethanol and sugar plants

Whether with preventive maintenance in the off-season or with predictive maintenance in the off-season, the important thing is to pay attention to variables and parameters to avoid greater losses in ethanol and sugar plants.

Within this scenario, Wortice Off-season Maintenance stands out, because:

- Determines, in advance, the need for maintenance services on a specific piece of equipment;

- Eliminate unnecessary disassembly for inspection;

- Increases equipment availability time;

- Reduces unplanned emergency work;

- Prevents damage from increasing;

- Takes advantage of the total lifespan of the equipment components;

- Increases confidence level in performance;

- It predetermines manufacturing interruptions to take care of equipment that requirements maintenance.

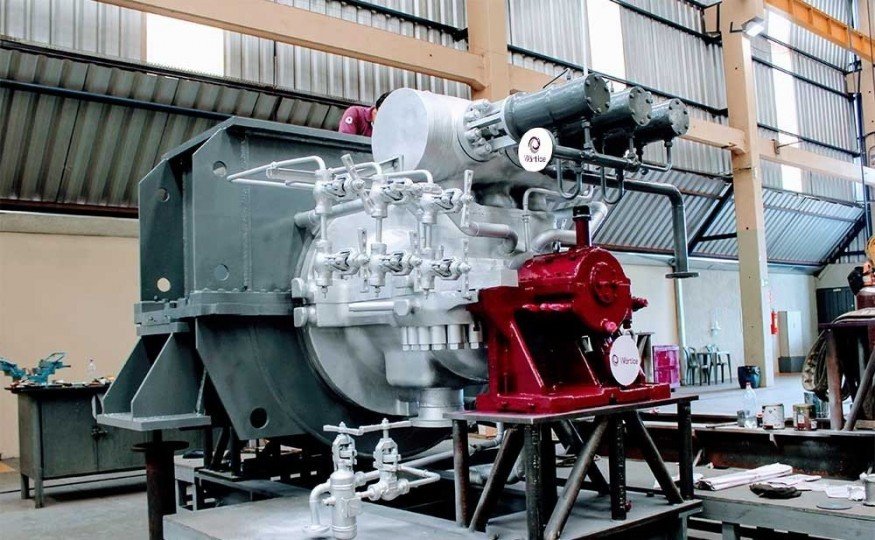

About Wortice

Wortice is a company based in Sertãozinho, in the country of São Paulo state, which has professionals with more than 45 years of experience in steam turbines, gearboxes and thermoelectric plants, offering several solutions such as:

- Factory maintenance

- Technical assistance in the field

- Manufacturing of Steam Turbines

- Turn Key Thermoelectric Plants

- Parts and components

- Maintenance and process engineering

Contact us and learn more about our history, products and services and find out why Wortice is your best solution for off- season maintenance in ethanol and sugar plants