Importance of preventive maintenance in the off-season

About preventive maintenance in the off-season, you must be aware, as performing it continuously ensures good functionality and increases the lifespan of your equipment.

Equipment is robust and contains sensitive components that need regular care. However, just having this equipment available does not necessarily ensure correct operation. Maintenance is required to be up to date to ensure good performance and full operating capacity.

What is off-season?

It’s the time when the soil is without agricultural activity, that is, an intermediate period between one harvest and another. At this time, some farmers plant short-cycle annual crops, which show great development even in bad weather conditions. The farmer's objective is to earn extra income in unfavorable times for the main crop.

What is the importance of preventive maintenance in the off-season?

In an industry, the full functioning of productive operational processes is a fundamental part of the organization, so it’s extremely important that preventive maintenance is always carried out in the off-season and that it becomes an annual practice.

This maintenance prevents some equipment from having defects or failures in the operation and ending up disturbing the operational process, as it has the same quality standard that it could offer. The interruption of production processes generates several problems that could have been avoided if preventive maintenance had been carried out in the off-season.

The importance of preventive maintenance in the off-season is to ensure the quality of the process, the full operation of the equipment on a daily basis and also to avoid unnecessary operating costs. Because in many cases, this investment becomes a great source of financial and operational savings.

What happens if preventive off-season maintenance is not performed?

If the component of a system, which constitutes a mechanism, is performing its work incorrectly, there will be an overload on the other devices that interact with it. Therefore, overloading will reduce the life of all parts in the set.

Preventive maintenance solves this problem by replacing the defective component, ensuring the preservation of the other mechanisms. If improvisation is carried out in any industrial mechanism, it will generate losses and even the complete stoppage of the industry's production.

Therefore, the main purpose of preventive maintenance in the off-season is to reduce costs and increase productivity.

Preventive maintenance in Wortice off-season

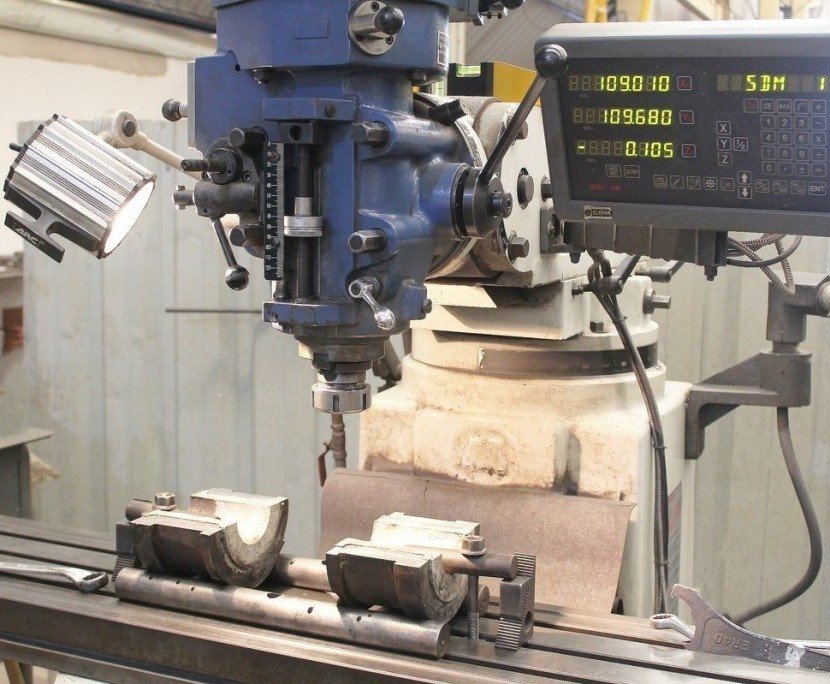

Wortice works with consolidated concepts of preventive maintenance engineering in the off-season. Starting with the optimization of equipment, seeking cost reduction, in order to meet better maintainability, reliability and availability of equipment in the processes.

With a high number of diversities and particularities, the engineering of preventive maintenance in the off-season requires a growing set of professionals and systems specialized in its maintenance. The company acts to reduce the number of reworks and losses that may happen.

Objectives for carrying out predictive and preventive maintenance during the off-season:

- Determine, in advance, the need for maintenance services on a specific piece of equipment;

- Eliminate unnecessary disassembly for inspection;

- Increase equipment availability time;

- Reduce unplanned emergency work;

- Prevent further damage;

- Take advantage of the total lifespan of equipment components;

- Increase confidence in performance;

- Determining manufacturing interruptions in advance to take care of equipment that requirements maintenance.

Learn more about preventive maintenance in Wortice off-season

Headquartered in the city of Sertãozinho, in the country of São Paulo state, Wortice is a steam turbine maintenance company that, in addition to having a specialized workforce, operates in accordance with all safety standards, always aiming at total excellence in the service dedicated to each customer.

In addition to offering preventive maintenance in the off-season, Wortice offers different industrial solutions in power generation, for example:

- Steam turbine manufacturing;

- Turn Key Thermoelectric Plants;

- Specialized engineering;

- Maintenance of condensers, steam turbines, gearboxes and power generators;

- Manufacture of parts and components.

For more information, contact us using the form below, telephone (16) 3511-0220 or send an email to comercial@Wortice.com.br