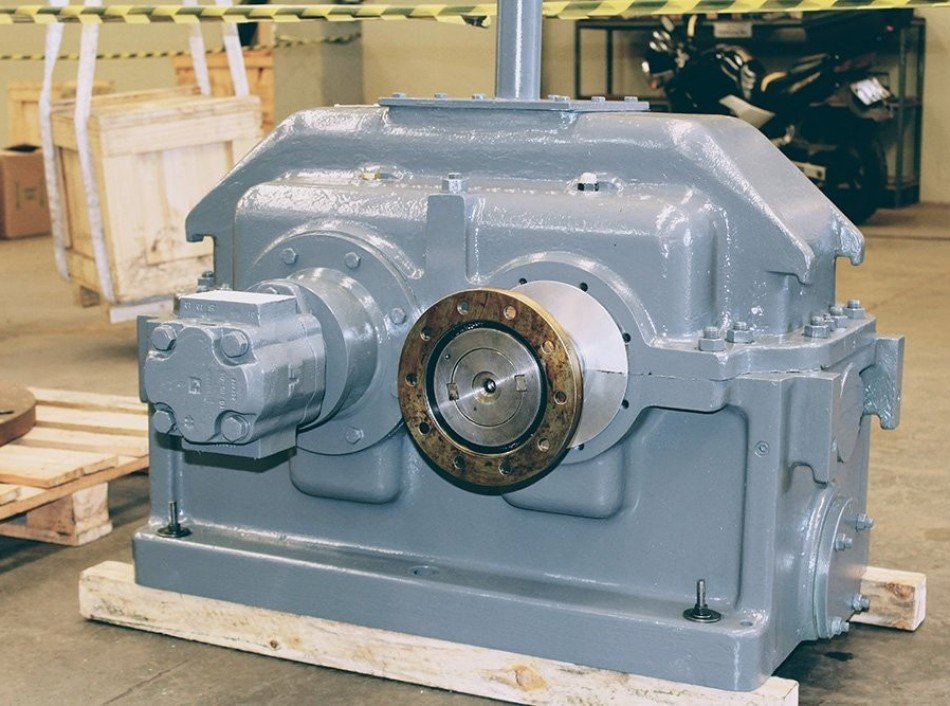

Gearbox Maintenance

About the maintenance of gearboxes, you should be aware, as performing it correctly guarantees good functionality and increases the equipment's lifespan.

A gearbox is a robust piece of equipment, it contains sensitive components that need regular care. However, just having the gearbox available does not necessarily guarantee correct operation. It is necessary that the maintenance of gearboxes is updated, ensuring their performance and their full operating capacity.

What is the importance of Gearboxes Maintenance?

If a component of a system, which constitutes a mechanism, is performing its work incorrectly, there will be an overload on the other devices that are in interaction with it. Therefore, overloading will reduce the useful life of the other parts of the set.

With the maintenance of gearboxes, the problem can be solved with the replacement of the defective component, to guarantee the preservation of the other devices. In any industrial mechanism, improvisation can generate losses and even the complete stoppage of an industry's production.

We can conclude that the main purpose of gearbox maintenance is to reduce costs and increase productivity.

Wortice maintenance of gearbox

Starting with the optimization of equipment, seeking cost reduction, in order to achieve better maintainability, reliability and availability of equipment in the processes.

With a high number of diversities and particularities, the maintenance engineering of gearboxes requires a growing set of professionals and systems specialized in their maintenance.

Therefore, we aim to reduce the number of reworks and losses that may occur.

We have a great knowledge in the industrial gearbox maintenance market, with professionals with over 40 years of experience.

We offer services on all models of equipment and all manufacturers.

Our objective is to offer efficient solutions, with specialized technical maintenance, aiming at excellence in quality, contributing to the industrial sector in an ethical and productive way.

We have specialized technical support at the factory and on site for:

- Corrective Maintenance for gearboxes

- Preventive maintenance for gearboxes

- Predictive maintenance for gearboxes

- Maintenance of gearboxes with a focus on reliability (RSRM)

- Renovation, Retrofit and modernization in gearboxes

- Operational interventions in gearboxes

- Replacement of parts and components in gearboxes

- Equipment installations, commissioning and start-up on gearboxes

- Inspections with technical report elaboration and performance monitoring in gearboxes

We also have specialized technical assistance on duty in the maintenance of gearboxes, with a team available for service in the field and a factory structure with 24-hour availability for maintenance of gearboxes.

- Total excellence in the service dedicated to each customer;

- Professionals with over 40 years of experience in the field;

- Specialized Technical Team with engineering support;

- Urgent and Emergency on-call 24 hours a day, 7 days a week;

- Technical team available for on-site assistance;

- Factory and Team available 24 hours a day;

- 100% Brazilian technology;

- Environmental & Social Responsibility.

Request a Quotation

Click on the button, fill out the form and we will get back to you shortly.

Request a Quotation

Types of Gearboxes Maintenance

Maintenance of Corrective Gearboxes

The maintenance of corrective gearboxes is performed after the occurrence of a failure or breakdown of a system or mechanism component, this type of maintenance is intended to put an item in a position to fully perform its own function again.

It is important to inform that this type of maintenance of gearboxes is the most expensive, which takes more time and can damage more.

Preventive Maintenance for gearboxes

The Preventive Maintenance for gearboxes obeys a previously designed standard, which establishes periodic stops with the objective of allowing the exchange of worn out parts for new ones, providing the perfect operation of the equipment for a previously determined period.

The preventive method provides a certain pace of work, providing operational stability for the smooth running of the processes.

Predictive Maintenance for gearboxes

The Predictive Maintenance for gearboxes is the one that indicates the real operating conditions of the equipment based on data that inform its wear or degradation process.

It’s this maintenance that predicts the lifespan of equipment components and the conditions for it to be put to good use.

Objectives of carrying out Predictive and Preventive Maintenance for gearboxes

- Determine, in advance, the need for gearbox maintenance services on a specific piece of equipment;

- Eliminate unnecessary disassembly for inspection;

- Increase equipment availability time;

- Reduce unplanned emergency work;

- Prevent further damage;

- Take advantage of the total lifespan of equipment components;

- Increase the confidence level in the performance of a gearbox;

- Pre-determine manufacturing interruptions to take care of equipment that requires gearbox maintenance.

Learn more about Gearbox Maintenance offered by Wortice

With its physical headquarters located in Sertãozinho, a city located in the country of São Paulo state, Wortice is a gearbox maintenance company that, in addition to having specialized workforce, operates in accordance with all safety standards, always aiming at total excellence in the service dedicated to each customer.

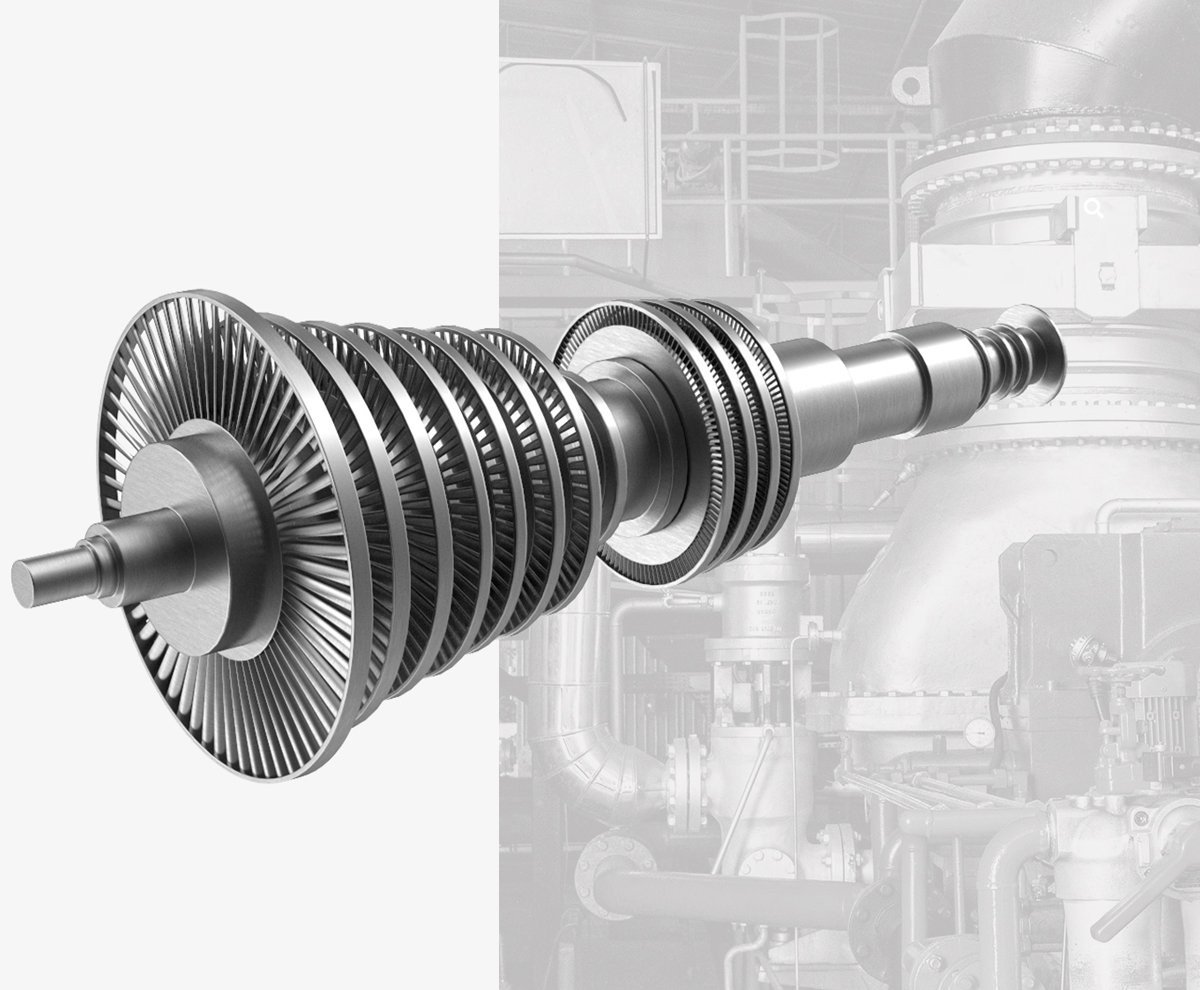

In addition to offering maintenance of gearboxes, Wortice offers different industrial solutions in power generation, such as:

- Steam turbine manufacturing

- Turn Key Thermoelectric Plants

- Specialized engineering

- Maintenance on condensers, steam turbines, gearboxes and power generators

- Manufacture of parts and components

For more information about gearboxes maintenance or other services that Wortice offers, contact us by phone (16) 3511-0220 or send an email to comercial@Wortice.com.br